Choosing between chunky and smooth salsa feels like a branding decision. Mild or hot. Rustic or refined.

In reality, it’s one of the most consequential production decisions you’ll ever make.

Texture doesn’t just affect mouthfeel – it dictates how your salsa moves, separates, fills, seals, and survives distribution. Many salsa brands fail not because their recipe is weak, but because their texture choice quietly breaks their production workflow.

This article explains how salsa texture determines everything downstream – from mixing and holding to filling, sealing, shelf life, and scalability – and why ignoring this relationship creates invisible but expensive problems.

Texture Is a Physical Property, Not a Preference

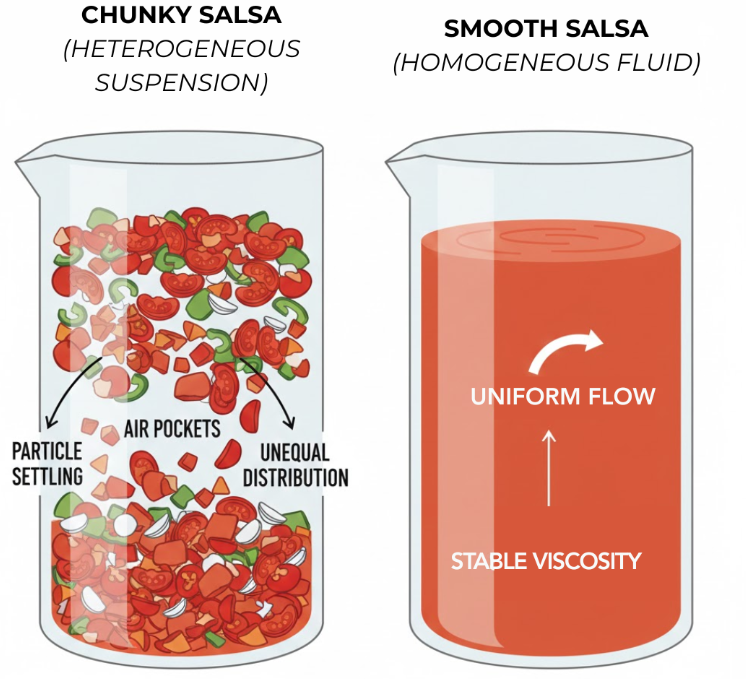

Salsa is a heterogeneous food system. Unlike ketchup or barbecue sauce, it contains discrete solid particles suspended in liquid.

The moment you choose chunky or smooth, you lock in:

- Flow behavior

- Settling rate

- Air entrapment risk

- Fill accuracy tolerance

Texture is physics. Physics doesn’t care about branding.

Chunky Salsa: The Most Demanding Texture in Condiments

Chunky salsa is popular because it signals freshness and authenticity. Operationally, it’s brutal.

Particle Size Variability Multiplies Risk

Chunky salsa contains:

- Irregular solids

- Uneven moisture content

- Variable density

Even small deviations in chop size create:

- Clogging during filling

- Inconsistent solid-to-liquid ratios

- Visible separation across jars

At scale, “mostly uniform” isn’t uniform enough.

Suspension Is Temporary, Not Stable

Chunks don’t stay suspended. Gravity always wins.

In production, this leads to:

- Early containers overloaded with solids

- Later containers diluted with liquid

- Customer complaints about “watery” product

Mixing harder isn’t a solution – it introduces shear damage and air.

Smooth Salsa: Easier Flow, Different Trade-Offs

Smooth salsa behaves more like a sauce, which simplifies some steps – but introduces new constraints.

Benefits of Smooth Texture

- Predictable flow rates

- Easier fill accuracy

- Lower clogging risk

- More consistent appearance

This is why smooth salsas often scale faster initially.

Hidden Risks of Over-Smoothing

However, smooth salsa:

- Oxidizes faster due to higher surface area

- Loses visual freshness cues

- Competes directly with sauces, not fresh salsas

From a market standpoint, smooth salsa sacrifices differentiation for operational ease.

How Texture Controls Every Major Production Step

1. Mixing and Holding Behavior

Chunky salsa requires continuous, gentle agitation to prevent settling – without damaging solids.

Smooth salsa tolerates pauses but is more sensitive to air incorporation.

Poor texture alignment at this stage causes:

- Micro-variations that become macro defects

- Jar-to-jar inconsistency

2. Transfer and Pumping Constraints

Chunky products stress transfer systems:

- Narrow pathways shear or block particles

- High pressure damages texture

- Low pressure causes uneven flow

Smooth salsa transfers easily – but reveals every inconsistency in viscosity.

Texture choice determines:

- Pump type

- Transfer speed

- Line stability

This is where many producers realize their workflow was built for the wrong texture.

3. Filling Accuracy and Visual Consistency

Chunky salsa is unforgiving during filling:

- Solids bridge unpredictably

- Fill weights fluctuate

- Visual defects multiply

This is why many commercial producers eventually rely on salsa packaging systems designed to handle particulate products consistently – not to speed up production, but to reduce variability that texture introduces.

Smooth salsa fills cleanly – but exposes defects instantly. Any separation or air bubble is immediately visible.

4. Oxygen Exposure and Shelf Life

Texture directly impacts oxidation.

According to the Institute of Food Technologists, products with higher surface area and air incorporation experience faster quality degradation.

- Chunky salsa traps oxygen between particles

- Smooth salsa incorporates oxygen during blending

Both degrade – but in different ways.

Without controlled filling and sealing, texture accelerates shelf-life loss long before spoilage is detectable.

5. Food Safety and pH Uniformity

Salsa relies on acidification rather than full thermal processing.

The U.S. Food and Drug Administration emphasizes that acidified foods must maintain consistent pH throughout the product – not just on average.

Chunky salsa risks:

- Micro-environments with higher pH

- Uneven acid distribution

Smooth salsa reduces this risk – but only if mixing is complete and consistent.

Texture determines how reliably safety parameters are met.

Why Texture Decisions Break Scaling Attempts

Most producers choose texture before understanding production constraints.

That leads to:

- Retrofitting processes to accommodate texture

- Fighting physics instead of designing for it

- Blaming equipment or ingredients instead of workflow

The most successful salsa brands reverse this:

- Define desired texture

- Design workflow around it

- Validate consistency before scaling

Texture-first thinking prevents expensive course corrections.

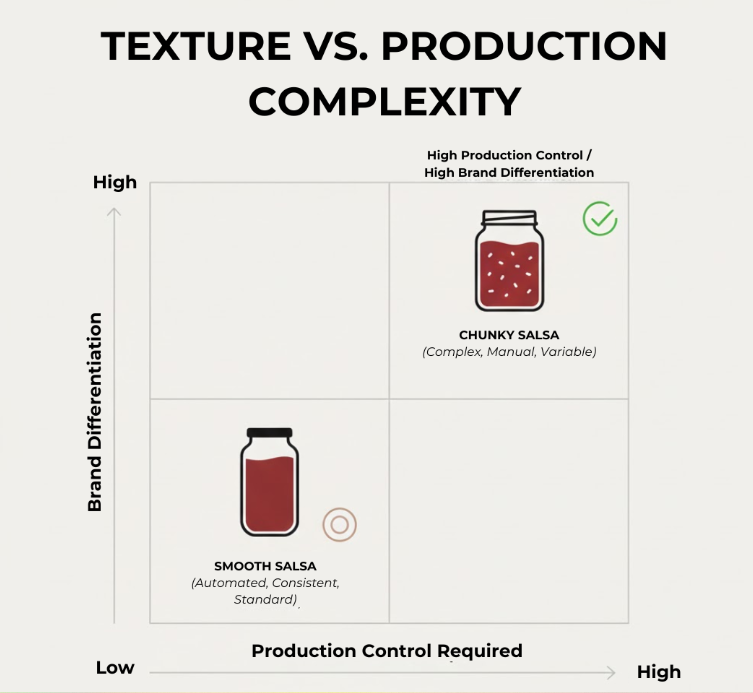

Choosing Texture Strategically, Not Emotionally

Here’s the hard truth:

- Chunky salsa demands tighter process control

- Smooth salsa demands stronger differentiation

Neither is “better.” One may simply be more compatible with your production reality.

If your workflow relies heavily on manual handling, chunky salsa will magnify every inconsistency. If your brand relies on freshness cues, smooth salsa may dilute your value proposition.

What Experienced Producers Do Differently

They treat texture as a system variable, not a style choice.

That means:

- Testing texture under real filling conditions

- Measuring separation across full runs

- Evaluating how texture behaves after sealing, not just before

- Accepting that packaging is part of texture control

Once this mindset shifts, consistency becomes achievable instead of aspirational.

Conclusion: Texture Is the Blueprint

Chunky vs. smooth isn’t a cosmetic decision – it’s the blueprint for your entire production workflow.

Texture determines how salsa moves, settles, fills, seals, and survives. When producers ignore that relationship, they inherit problems they don’t know how to diagnose. When they respect it, consistency becomes repeatable.

If this guide reframed how you think about salsa texture, share it with another producer – or explore deeper resources on designing food systems that scale without compromise.

Culinary Expert

Edward brings a wealth of knowledge to the Food Meal Trail team, specializing in culinary techniques and gourmet cooking. With years of experience in professional kitchens, he shares his insights through engaging articles that simplify complex recipes. Edward is passionate about helping home cooks elevate their skills and create memorable dining experiences.

Culinary Expert

Edward brings a wealth of knowledge to the Food Meal Trail team, specializing in culinary techniques and gourmet cooking. With years of experience in professional kitchens, he shares his insights through engaging articles that simplify complex recipes. Edward is passionate about helping home cooks elevate their skills and create memorable dining experiences.